Welcome to Our Company

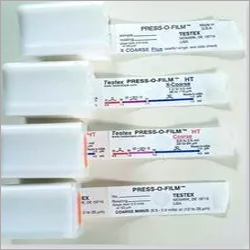

Shot Grit Blasting Comparator

Product Details:

- Output Visual surface profile assessment

- Product Type Surface Roughness Comparator

- Usage For visual and tactile comparison of surface profile after shot/grit blasting

- Standard ISO 8503-2 / ASTM D 4417 / SSPC-VIS 1 / SANS 6769:2003 / DIN EN ISO 8503-1

- Control Type Manual

- Accuracy Within specified international standards

- Size Portable pocket-size disc

- Click to View more

X

Shot Grit Blasting Comparator Price And Quantity

Shot Grit Blasting Comparator Product Specifications

- Surface Roughness Comparator

- Portable pocket-size disc

- Approx. 60 mm diameter, thickness 3-6 mm

- ISO 8503-2 / ASTM D 4417 / SSPC-VIS 1 / SANS 6769:2003 / DIN EN ISO 8503-1

- Within specified international standards

- Metallic Grey/Silver

- Manual

- Approx. 50 g

- Visual surface profile assessment

- For visual and tactile comparison of surface profile after shot/grit blasting

Product Description

Get the Shot Grit Blasting Comparator with Matchless quality and Astounding precision for inspection of blasted steel surfaces. Offered at Competitive Pricing, this marvelous tool provides Fine, Medium, and Coarse profile samples, spanning 25 to 70 microns. The sturdy stainless steel disc is highly resistant to corrosion and meets rigorous ISO 8503-2 and ASTM D 4417 standards. Grab yours for visual and tactile comparisons post shot/grit blastingsupplied with a protective carrying case and manual. Portable, accurate, and practicalideal for exporters, manufacturers, suppliers, and traders across India.

Practical Assessment Tool for Surface Profiles

The Shot Grit Blasting Comparator is specifically designed for inspection of blasted steel surfaces, enabling both general and specific use in quality control. Its special features include three distinct surface profile samples (Fine, Medium, Coarse), high durability due to stainless steel construction, and superior corrosion resistance. This comparator offers reliable results through manual eye-and-touch comparison, making it essential for consistent surface finishing evaluation across industries.

Supply Ability and Market Value Insights

Our Shot Grit Blasting Comparator is readily available for prompt shipping from key FOB ports across India. The market value is enhanced by our commitment to offering the lowest price and competitive list price for bulk orders. Main domestic markets are well-serviced, ensuring fast and dependable delivery for manufacturers, exporters, suppliers, and traders. The product is packaged securely to maintain its quality and accuracy, supporting ongoing supply requirements.

Practical Assessment Tool for Surface Profiles

The Shot Grit Blasting Comparator is specifically designed for inspection of blasted steel surfaces, enabling both general and specific use in quality control. Its special features include three distinct surface profile samples (Fine, Medium, Coarse), high durability due to stainless steel construction, and superior corrosion resistance. This comparator offers reliable results through manual eye-and-touch comparison, making it essential for consistent surface finishing evaluation across industries.

Supply Ability and Market Value Insights

Our Shot Grit Blasting Comparator is readily available for prompt shipping from key FOB ports across India. The market value is enhanced by our commitment to offering the lowest price and competitive list price for bulk orders. Main domestic markets are well-serviced, ensuring fast and dependable delivery for manufacturers, exporters, suppliers, and traders. The product is packaged securely to maintain its quality and accuracy, supporting ongoing supply requirements.

FAQs of Shot Grit Blasting Comparator:

Q: How is the Shot Grit Blasting Comparator used during surface inspection?

A: The Shot Grit Blasting Comparator is used by visually and manually comparing the blasted steel surface against the three provided profile samplesfine, medium, and coarse. This helps inspectors ensure that the surface finish meets required specifications.Q: What are the main benefits of using stainless steel for the comparators material?

A: Stainless steel offers high corrosion resistance and remarkable durability, ensuring accurate profiles and long-lasting performance even in harsh industrial environments.Q: When should this comparator be employed during the blasting process?

A: The comparator should be used after shot or grit blasting, during surface preparation, to verify that the steel surface achieves the correct finish before further coating or painting.Q: Where is this product primarily supplied and distributed?

A: The Shot Grit Blasting Comparator is supplied to domestic markets across India, with bulk shipping available from major FOB ports for exporters, manufacturers, suppliers, and traders.Q: What standards does the comparator comply with for quality assurance?

A: It is manufactured to meet international standards including ISO 8503-2, ASTM D 4417, SSPC-VIS 1, SANS 6769:2003, and DIN EN ISO 8503-1, guaranteeing precise and reliable results.Q: What is the process for surface profile comparison using this tool?

A: Inspectors match the blasted steel surface by eye and touch to the comparators actual metal samples, determining if the finish falls within the 25 to 70 micron range specified by standards.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Surface Testing Equipment' category

|

BOMBAY TOOLS CENTRE (BOMBAY)

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |